Magnetic systems

Various series of shutters and casting separators with integrated magnets.

Besides a wide range of typical magnetic systems, Olmet Italy can design also custom-made accessories in accordance with each and every customer’s specific requirements.

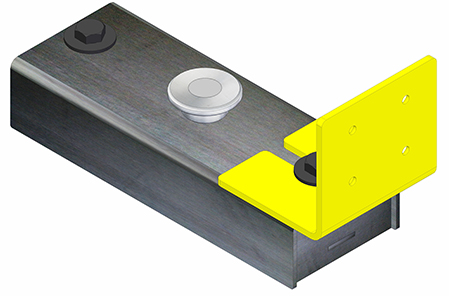

OSM series

OSM series, rapid and rational formwork systems, with integrated magnets for manufacturing high quality panels.

The OSM mostly consists of an external steel box, an integrated push button for activation and deactivation and an embedded permanent magnet. Strength of adherence (magnetic force): 900 ÷ 2100 kg.

The OSM system is manufactured in 2 models::

Strength of adherence: 900 Kg

– L: 320 mm.

– W: 80 mm.

– H: 65 / 85 mm. (with button on)

– Hd: 95 mm. (with button off)

Strength of adherence: 2100 kg

– L: 320 mm.

– W: 120 mm.

– H: 65 / 85 mm. (with button on)

– Hd: 95 mm. (with button off)

OSM series - Typical accessories

PRSQ fits for a rapid and safe fixing of casting separators and shutters. The system ensures the maintenance of the formwork perpendicularity. It is suitable for casting thicknesses from 200 to 450 mm.

PRSQLA is an L-shape fixing device meant for wooden or aluminium shutters. It is made of high resistance steel and provided with 6 lateral holes of 8 mm. diameter. The angular fixing can be removed and changed. The system is provided with no.2 M16 screws, quality 8.8, with increased section washer. Screw and washer are galvanized. It is suitable for casting thickness ranging from min. 200 to max. 450 mm.

PRSQLB is an L-shape fixing device meant for wooden or aluminium shutters. It is made of high resistance steel and provided with 6 lateral holes of 8 mm. diameter. The angular fixing can be removed and changed. The system is provided with no.2 M16 screws, quality 8.8, with increased section washer. Screw and washer are galvanized. It is suitable for casting thickness ranging from min. 80 to max. 200 mm. The L fixing can be screwed or welded also on steel shutters.

PRFA is an L-shape fixing device meant for wooden or aluminium shutters. It is made of high resistance steel and provided with 6 lateral holes of 8 mm. diameter. The angular fixing can be removed and changed. The system is provided with no.1 M16 screw, quality 8.8, with increased section washer. Screw and washer are galvanized. It is suitable for casting thickness ranging from min. 80 to max. 400 mm. The L fixing can be screwed or welded on steel shutters.

PRANM is an anchoring system for steel casting separators provided with handling bar. The angular fixing can be removed and changed. It is suitable for casting thickness ranging from min. 80 to max. 200 mm. It is recommended for fixing doors and windows inserts even of huge dimensions. It fits for thicknesses up to 450 mm. The system is coupled with OSM model magnets having 900 / 2.100 kg. strength of adherence. The system is provided with no.2 M16 screws, quality 8.8, with increased section washer. Screw and washer are galvanized.

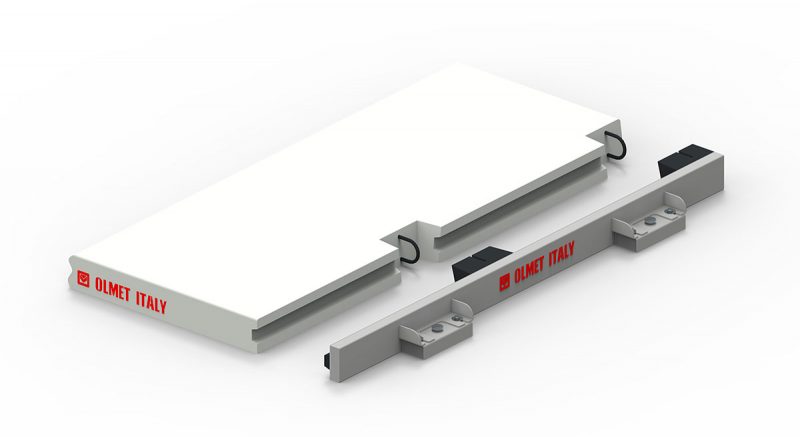

Uni series

UNI series, shuttering systems based on magnets with fast activating / deactivating push-button for standard thicknesses.

It can be applied on steel shutters and casting separators to produce walls of thickness ranging from min. 80 to max. 350 mm. The profile can be flat, tongue and groove shaped in accordance with specific design, with steel or rubber-steel chamfers. This system can be positioned either manually or with a robotic system.

The shutters can be manufactured as custom-made as far as length, height and shape, with or without chamfers, with vertical or inclined shuttering, with milled or not milled. Our Technical Dept. can devise any technical solution.

This system can be used for solid or three-layer walls. Double-casting side separators are available on request:

- Shutter length: 300 mm. ÷ 6.000 mm;

- Height: 50 mm ÷ 400 mm.

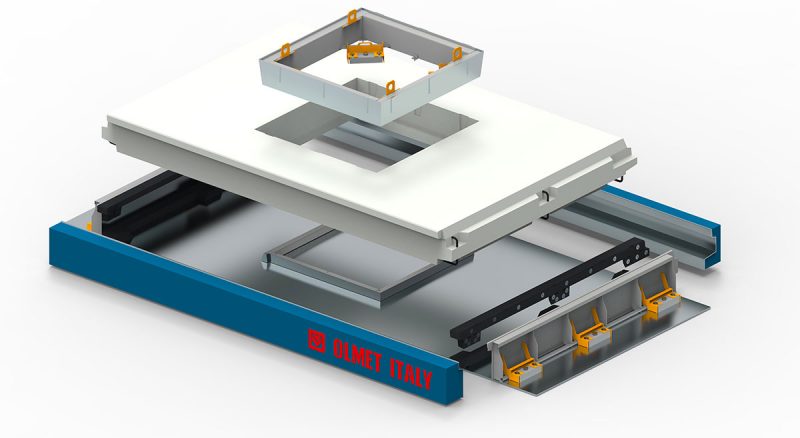

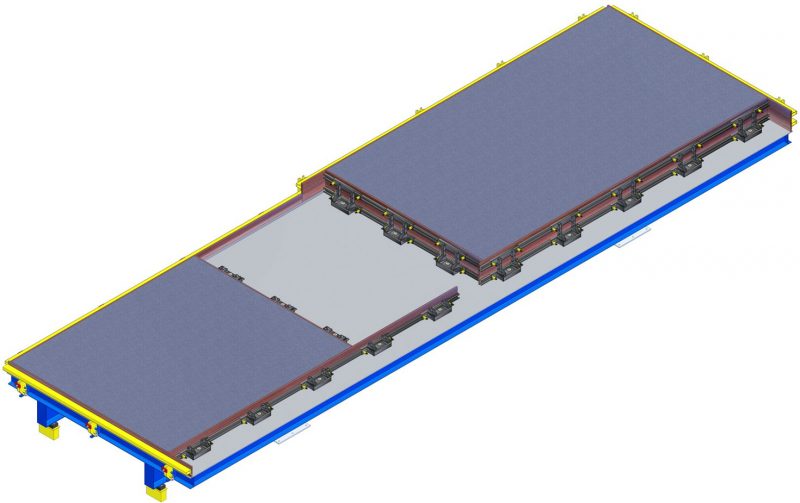

Combi series

COMBI series, shuttering systems based on integrated magnets with fast activating/deactivating push-button for special panels.

These systems have been designed for pre-casting companies producing special panels with various inserts. They are made of first-quality steel and are guaranteed for lasting. They can be used for solid or three-layer walls of 80 to 400 mm. thickness.

Their width can range from 400 to 3.600 mm. The system is provided with OSM series magnets of 900 / 2.100 kg strength of adherence.

They have 2 holes for hooking by a special OLMET ITALY lifting crane beam.

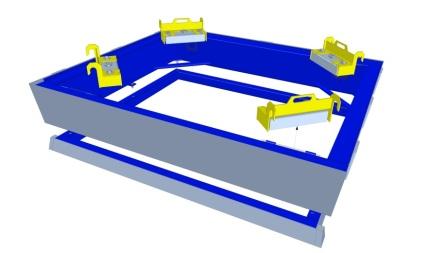

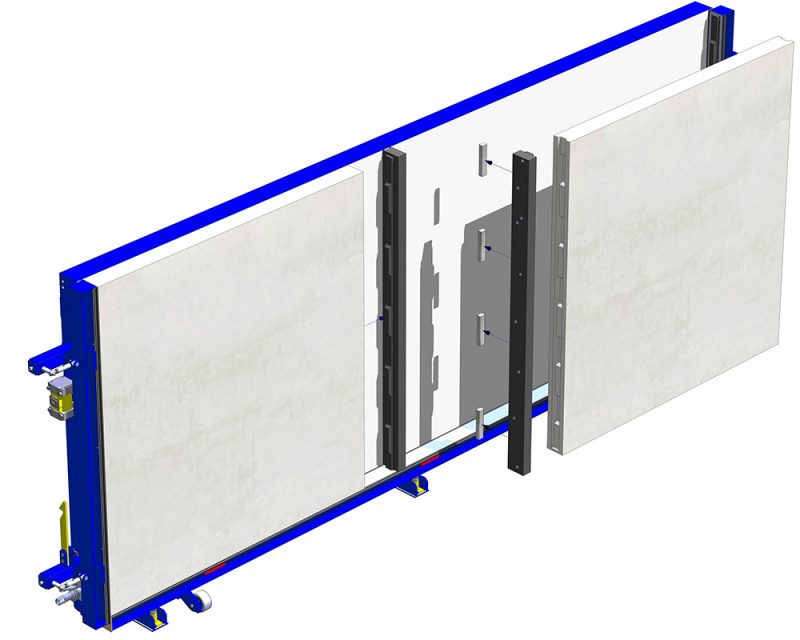

Windor series

WINDOR series, created for manufacturers of pre-finished walls for residential buildings.

The WINDOR series is specifically designed for the creation of window and door holes on both single-layer and three-layer façade panels. These elements are fixed onto the formwork by permanent magnets and are custom-made on specific request.

They are manufactured using reinforced steel of huge thickness and equipped with lifting hooks for the over head travelling crane.

- Minimum size that can be manufactured: 350 x 350 mm.

- Maximum size that can be manufactured: 3.500 x 4500 mm.

- Casting thickness: from 80 to 450 mm.

- Available on request also with different slope on each side.

This system can be used for panel production on vertical battery formworks.

The WINDOR series items are fixed onto vertical side elements usually with no.4 OSM series magnets of 2.100 kg strength of adherence. Also ‘MFSS-H+’ SERIES accessories are available for this purpose.

This system is supplied complete with a lifting crane-beam allowing a quick and safe handling of the false-formworks.

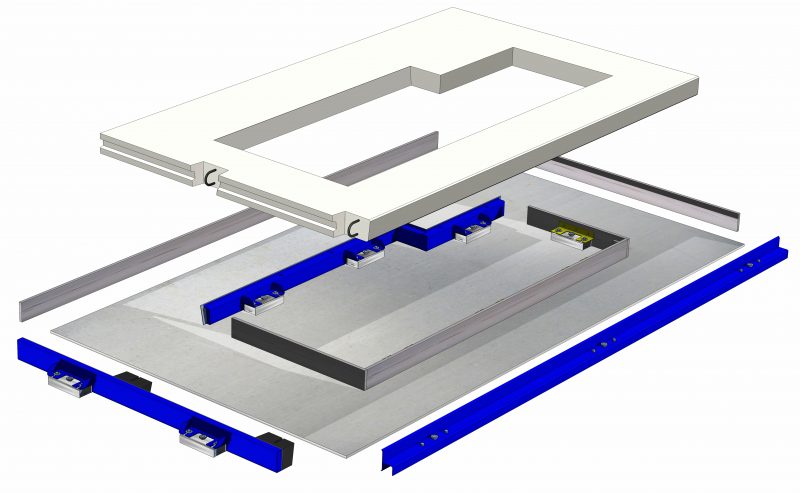

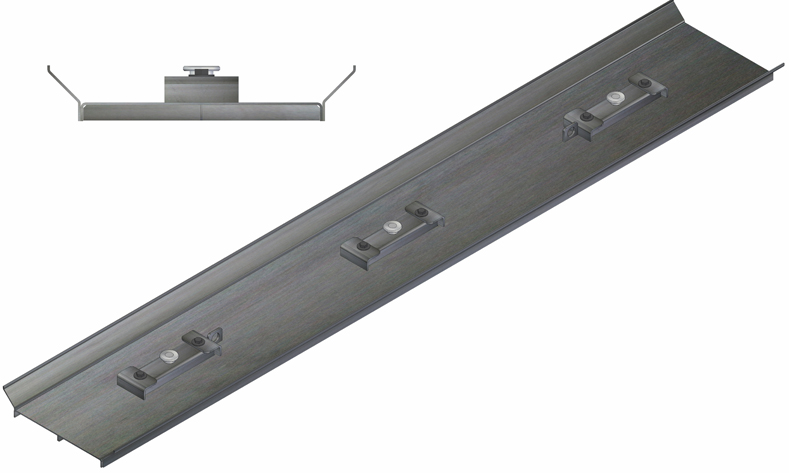

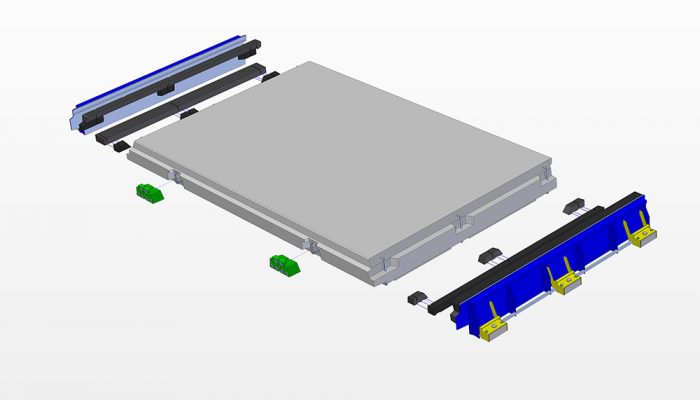

Slab series

Longitudinal and transverse casting separators for manufacturing floor slabs.

Longitudinal separators are fixed by OSM-series magnetic boxes. They can be flat or moulded as per Buyer’s requirements.

Transverse separators are fixed by OLM-series round magnets. They are moulded with recesses for placing the steel reinforcement and/or pre-stressing strands.

These casting separators can accommodate any type of inserts. They can be used to manufacture either pre-stressed slabs or slabs with standard reinforcement. In the latter case, they can be easily handled and stored also by our handling robot (shutter positioner).

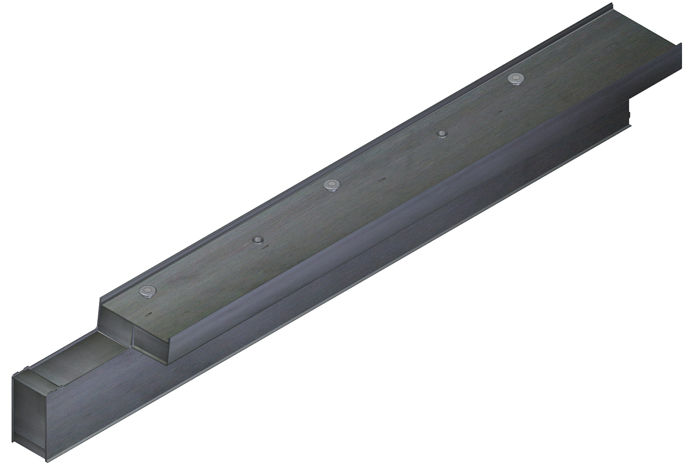

DCF series

Shutters and casting separators with double casting face, suitable for manufacturing slabs, curtain walls, external walls, etc., with a set thickness.

They are fixed by OSM-series magnets, whose number depends on the shutter or separator thickness and/or length.

The “DCF” series separators can be flat, moulded (groove & tongue) or with chamfers (rubber or steel-rubber) and can be used with any other shuttering elements, They can also be further implemented by the application of made-to-order polypropylene magnetic inserts.

Positioning, activating and removal operations on them can be carried out either manually, or by means of a special crane-beam or by a shuttering robot.

They can also be cleaned by means of a cleaning machine on both sides.

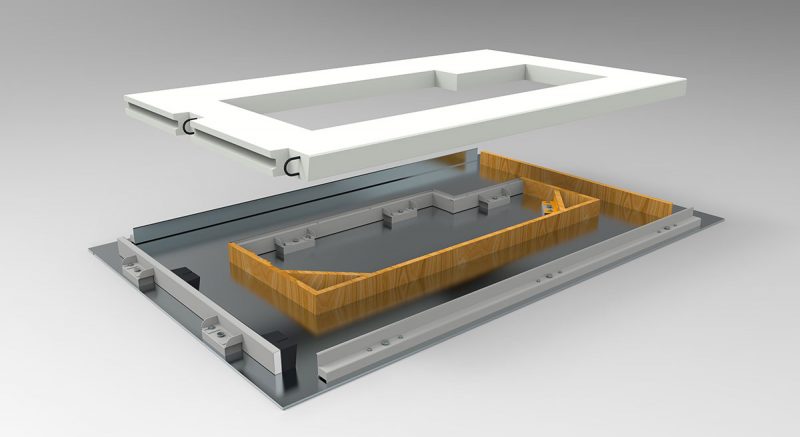

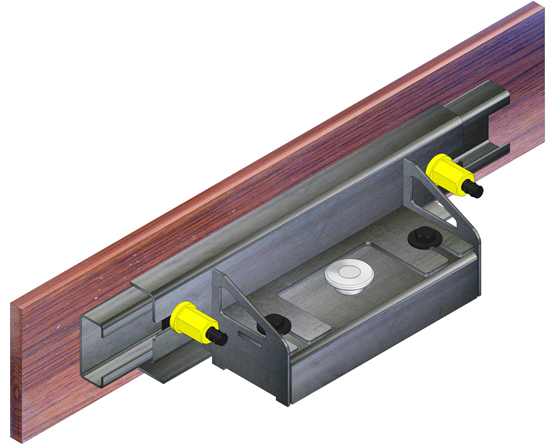

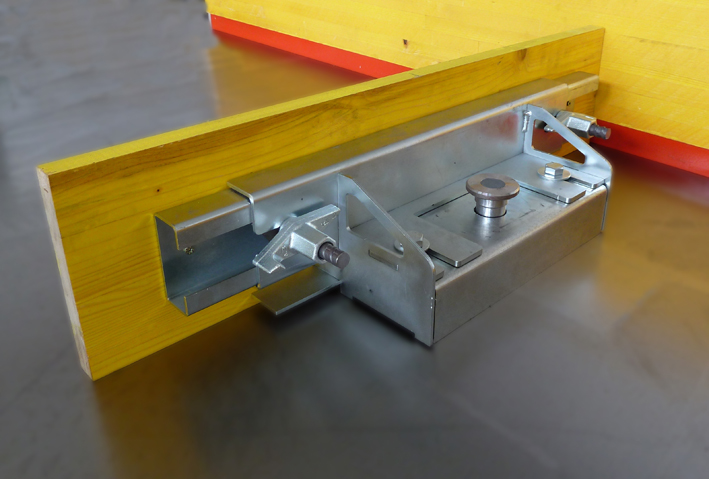

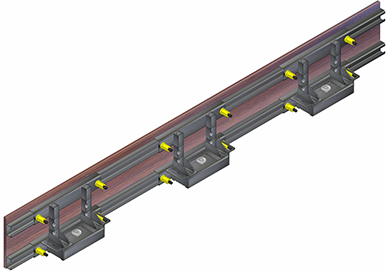

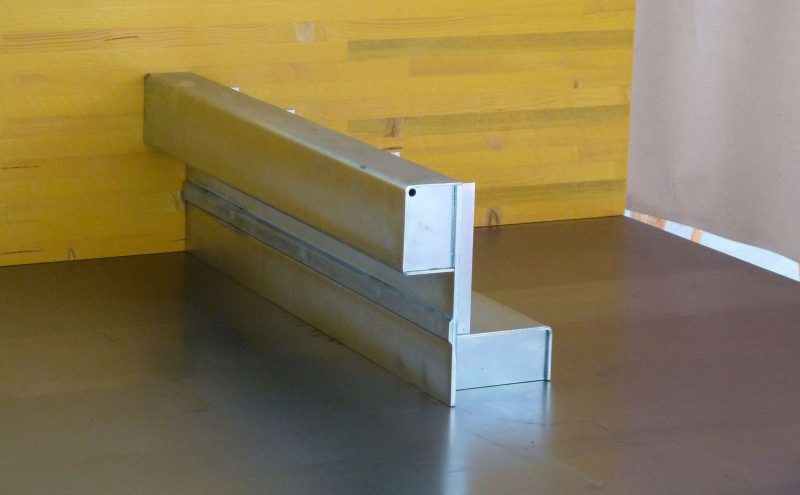

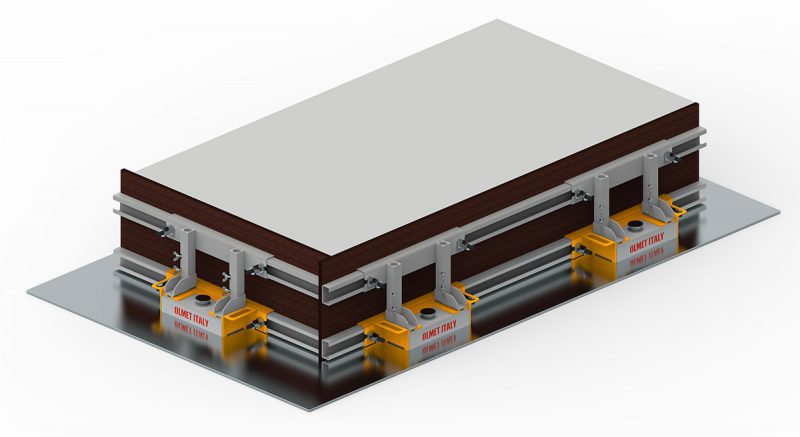

MFFS series

Magnetic fixing and supporting system for wooden shutters, suitable to manufacture concrete elements of varying thickness and moulding, especially advantageous when compared to steel shutters when too many height variations are to be foreseen.

The “MFSS” group consists of:

- a channel profile (adapter) to be bolted onto any wooden plank;

- a special support complete with OSM-series magnetic box for clamping to the casting surface.

It can be used to reach any length and/or height, also in combination with other shuttering systems (both longitudinal and transverse) and to create door and window frames with utmost flexibility.

It is an easy, fast and safe device to set up and manually handle. It can be applied onto any type of wooden planks (plywood, flake board, multilayer) or onto PVC boards. The shuttering boards are screwed from the backside, so that no sign is visible on the cast concrete element surface.

It can be manufactured as a double-face item as well.

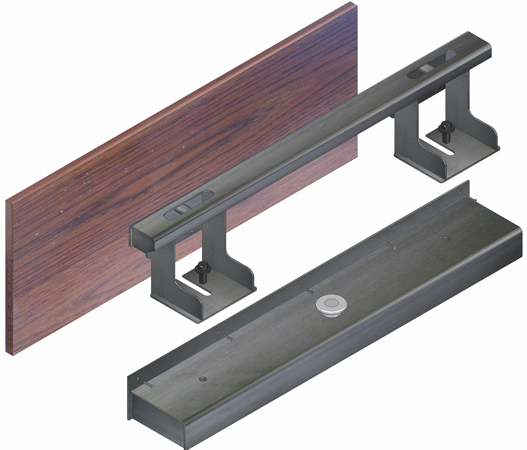

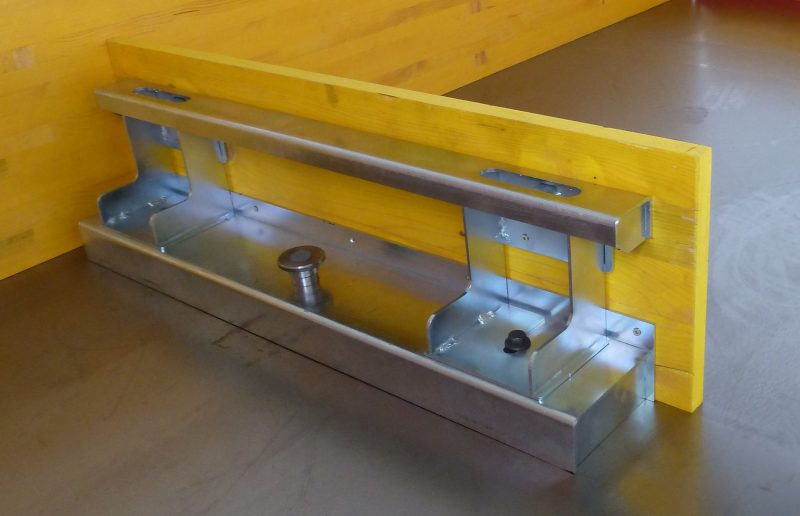

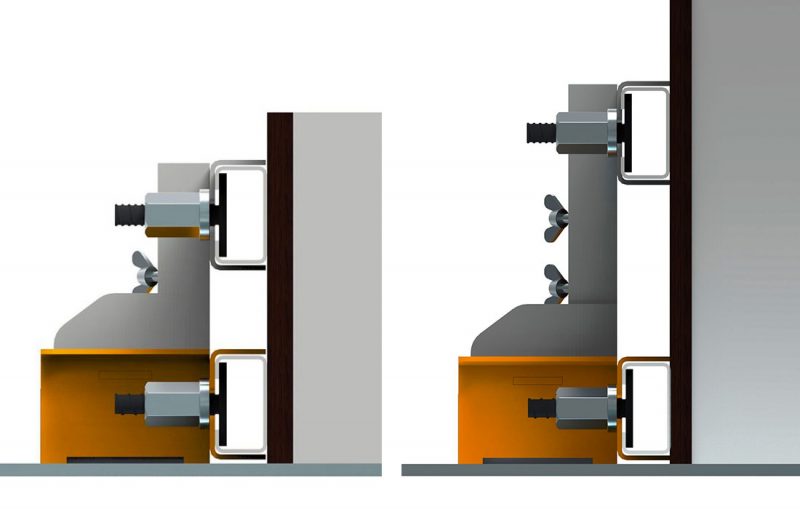

MFFS-H+ series

Multi-purpose adapter for longitudinal and transverse shutters, as well as doors and windows negative frames.

The “MFSS-H+” group consists of:

- a channel profile (adapter) to be bolted onto any wooden plank;

- a special support complete with OSM-series magnetic box for clamping to the casting surface;

- an upswing system to make it possible to cast panels of different heights.

It is an easy, fast and safe device to set up and manually handle.

It can be used to reach any length and/or height, also in combination with other shuttering systems, both longitudinal and transverse, and to create door and window frames with utmost flexibility.

It is extremely flexible, as it gears to any length and height by changing the wood plank to be applied onto it.

The shuttering boards are screwed from the backside, so that no sign is visible on the cast concrete elements.

BT series

Magnetic double-face casting separator with one or more interchangeable upswings (height extensions).

The “BT” group consists of:

- a base-shutter with integrated magnets;

- one or a set series of height extension profiles of different heights to be bolted on top of the base-shutter.

This ensures the highest versatility and flexibility while being also compatible with handling robot applications.

Being a double-face component, it makes it possible to use a single item to adjust the casting height, thus wasting less space.

SFT series

Fully steel-made magnetic shuttering system allowing for the application of different front-inserts at any height of its single casting face.

This shuttering group consists of:

- a base-shutter with integrated magnets;

- one or a set of plain, moulded or composite casting-face plates, possibly with inserts fastened onto them, which can be positioned at any height.

It is particularly suitable for solid or sandwich walls, while ensuring utmost flexibility and allowing for manual handling in an easy and safe way.

The fully steel structure can however accommodate also wooden shutters, according to production requirements.

WFSH series

Magnetic fixing and supporting system for wooden shutters, especially suitable to manufacture concrete elements of varying moulding and of any thickness.

The “WFSH” group consists of:

- a casting separator to be bolted onto the wooden plank, complete with OSM-series magnet, typically of 2100 kg. adhesive force;

- a special height extension to fasten wooden planks of any height from min.100 to max.400 mm.

It can be applied onto any type of wooden planks (plywood, flake board, multilayer) or onto PVC boards.

This system is to be handled by means of OHT crane using a crane-beam to save time, however it is easy and fast to set it in place when it comes to fasten/unfasten the shutter to it.

These shuttering groups can accommodate any type of inserts, special mouldings and chamfers as well.

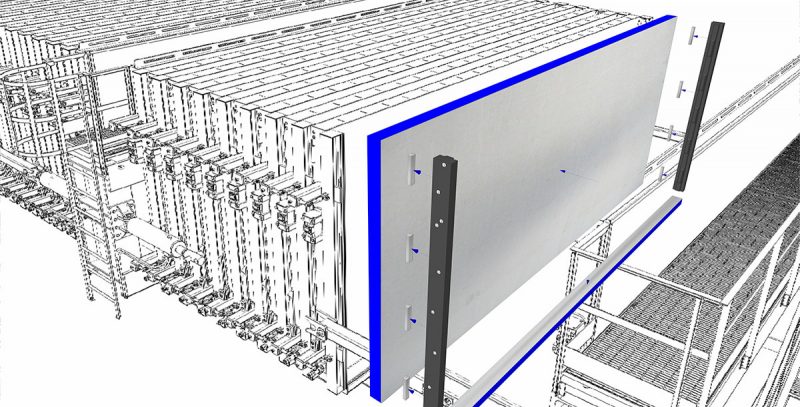

VCS series

Casting separator especially designed to split each single casting cavity (pocket) of a vertical battery formwork into wall panels of varying size.

The “VCS” separator adheres onto the casting plate of the vertical elements of a battery formwork by means of our standard magnets with pushbutton for fast attaching & detaching and is supplied complete with tightening gaskets to perfectly adhere to the casting surface.

These casting-separators can have both plain or moulded edges.

To make handling easier, a lifting point in the form of an eyebolt is pre-set, This can be screwed onto the upper edge of the casting separator.

MULTIVAR series

The magnetic fixing system for formworks “ Multivar group” includes:

- a channel profile (adaptor) that can be bolted onto any wooden board;

- a special support complete with a OSM series magnetic box to adhere to the casting surface;

- an upswing enabling one to cast panels having different heights.

It is a simple system, fast and safe to be assembled and manually handled.

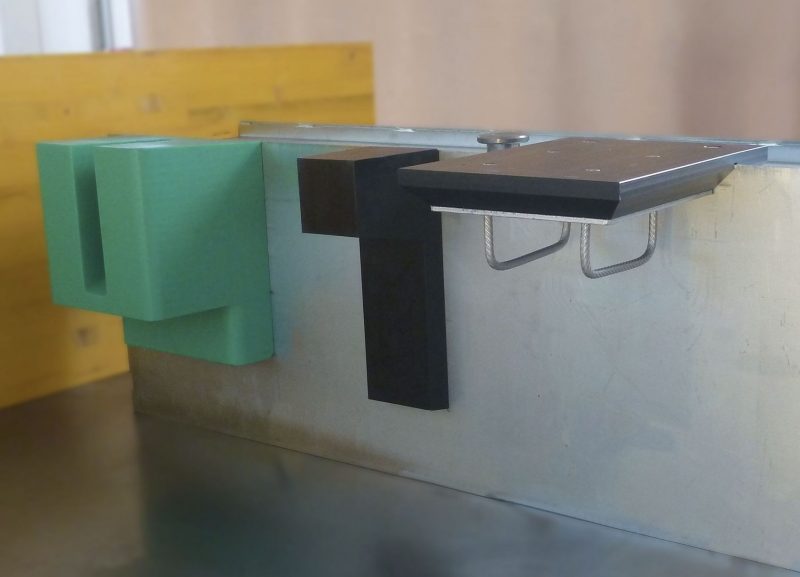

INSERT series

Inserts made of polypropylene material of any shape and size, with embedded magnets.

They are special inserts, made-to-order, easy to use and long-lasting thanks to polypropylene, a high density material (HD 1000).

They are demoulding oil proof and resistant to high temperatures. They can be easily cleaned, as concrete doesn’t stick to them.

In case they get broken, they can be replaced very easily (in max. of couple of minutes), simply by using a hex wrench or a screwdriver. They very easily adhere to the casting separators.

Suitable for clamping:

- lifting anchor bolts;

- steel plates;

- supports for embedding PVC pipes, etc…

It is possible to create also:

- niches of trapezoidal shape;

- niches of truncated-conical shape;

- special niches of any other shape.

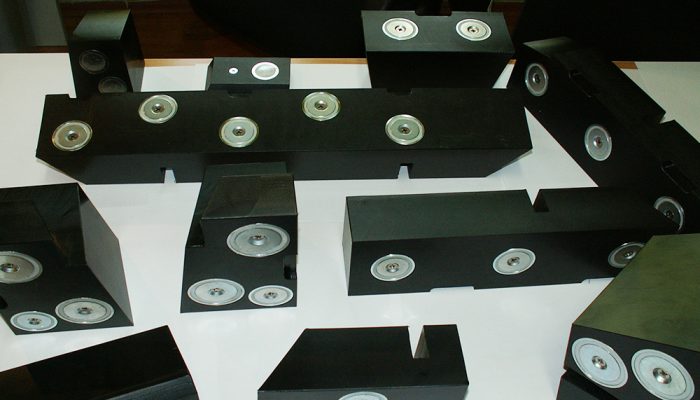

ROUND series

Round shape magnets with steel base, extremely powerful, compact and versatile.

Different models are available, to suit all requirements.

HDL series

Special handling spreaders (transverse crane-beams) used to remove and handle formwork profiles, side-elements and casting separators or any shuttering-group, both when the panel design is outlined and at demoulding stage.

All handling crane-beams are custom-made according to specific requirements.

The lifting movement is normally carried out by an electric chain hoist.

They are extremely versatile and can be freely used for different applications. Many advantages are provided in terms of saving time and labour, increasing speed and, safety during operations, improving working conditions and safeguarding the formwork profiles.

LIFTING-BEAM / HANDLING-DEVICE TO LIFT AND HANDLE THE MAGNETIC ACCESSORIES

- load-bearing capacity: 300 kg.

- distance between the track lines: 900 mm.

GASKET series

SERIES “GF”: ITEM GFP – GFS – GF10X45° – GF15X45° – GF20X45° made of cured rubber and steel material.

This series is designed to be fixed onto formworks by means of welding or riveting.

It is manufactured with flat or chamfered profile (45°) in segments of max. 100 cm. length.

It is resistant to chemicals as demoulding agents and to high temperatures. It is guaranteed for lasting.

On specific customer’s request, it is possible to manufacture special profiles as well.

Necessari

Necessari

Funzionali

Funzionali

Statistiche

Statistiche Marketing

Marketing