6 October 2017

Latest machinery for steel plate processing (August 2017)

Olmet Italy has always strongly believed in innovation and has always been investing in the latest technologies.

In 2017 it has renovated the set of machinery at its manufacturing unit, by adopting the latest and most advanced technologies for steel plate processing:

- Fiber laser shearing by «w-fiber 20-60» laser machine (2000x6000mm)

- Hydraulic press-bending by 9-axis press-bending «Futura» machine (6000mm – 640ton/mt)

Such latest-generation machines have been manufactured by the Italian company Warcom, leader in this business line, and they enable the operator to:

- carry out laser shearing of any geometry on carbon steel, stainless steel and aluminium plates, up to 15 mm thickness;

- carry out high precision press-bending operations, entirely by a laser-controlled bending workstation.

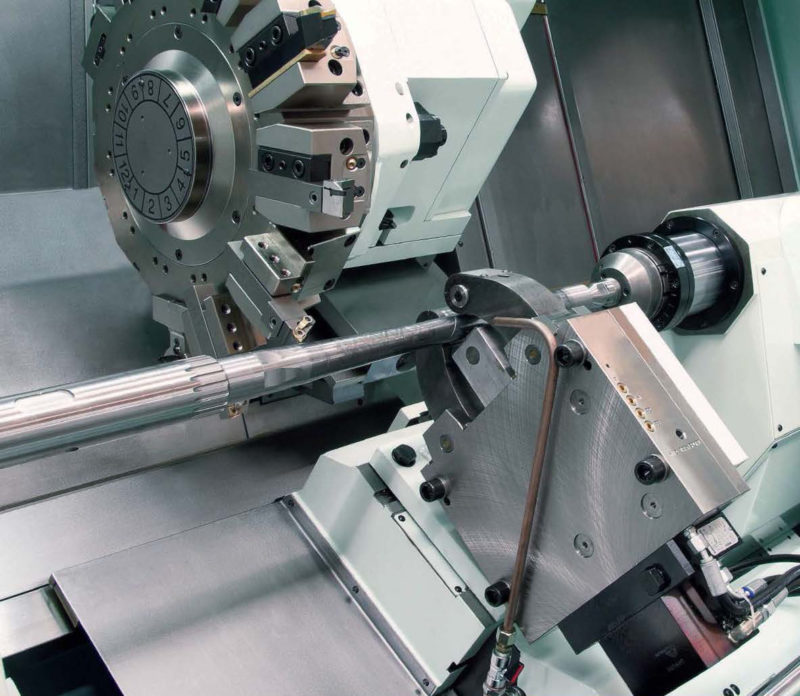

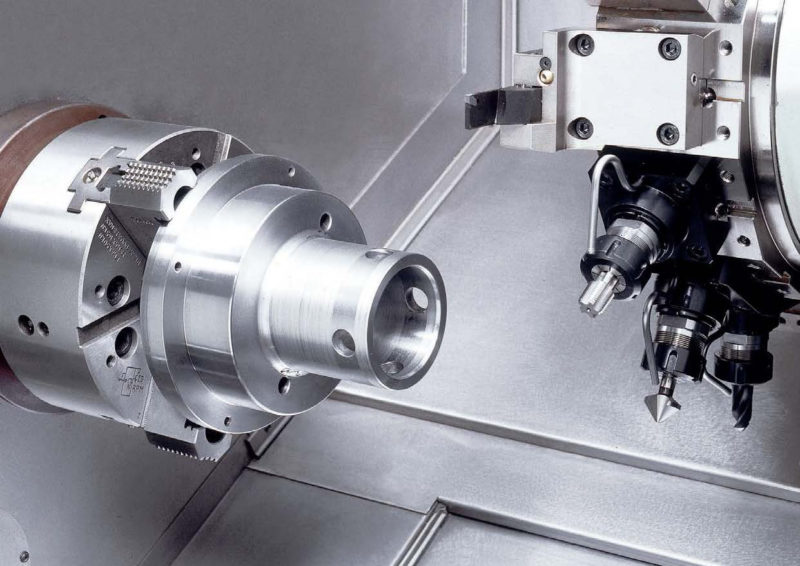

Further to this, Olmet Italy has recently purchased also a new CNC lathing center – item BIGLIA “B-1200-Y”, with a huge capacity for plate chip removal.

Complete with automatic turret with 12 working positions, power-assisted, with combined axis C and Y, making it a real 4-axis working station.

All this makes it possible to carry out any lathing, milling and tapping process in an easy and accurate way, both in-axis and out-of-axis.

Numeric Control System: Fanuc 18i-T, with full-colour wscreen 10.4″, with the “manual guide” innovative software.

Necessari

Necessari

Funzionali

Funzionali

Statistiche

Statistiche Marketing

Marketing