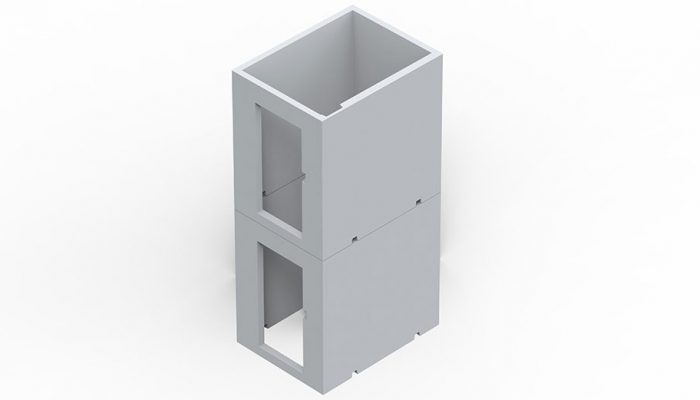

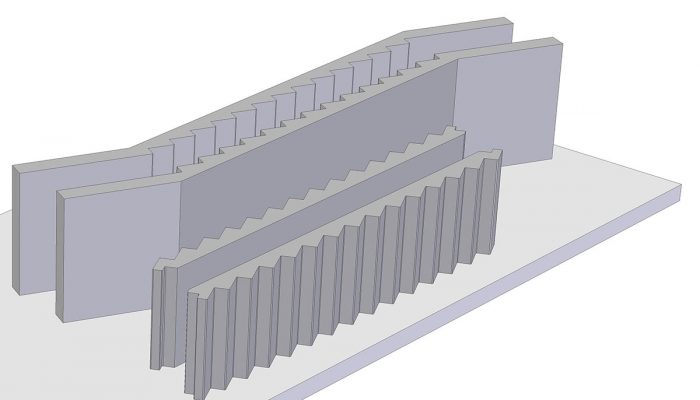

Formworks for single-block-elements

The formworks, optimized to manufacture single-block multi-section concrete elements within short transformation times, enable the operator to manufacture a wide range of pre-cast concrete elements as they are manufactured as modules to be differently combined.

Formworks belonging to this category are for example cabins for power sub-stations, garages, dwelling units, elevator shafts, bath cells (bathrooms and toilets), ventilation blocks, staircases, septic / sewage tanks, water reservoirs and many other concrete elements.

The Construction System by “SINGLE-BLOCK” elements assures smooth inner walls without ribs and a constant inner surface along all the horizontal sections.

It makes it possible to obtain a very resistant structure, extremely stiff and thus less subject to settlement shocks, which might occur during transport or erection on site, so that the whole single-block element can be moved complete with doors and windows, bathroom fittings and any electro-mechanical equipment, ready to be put into operation.

Advanced kinetic systems enable the formworks to gear themselves to the section to be manufactured.

Tested electro-hydraulic installations do prevent the false-formwork from changing the shape at casting stage, granting excellent dimension tolerances of the pre-cast concrete elements.

Variable dimensions:

- length: 3.000 ÷ 12.000 mm.

- width: 1.500 ÷ 4.000 mm.

- height: 2.000 ÷ 3.700 mm.

- thickness: 80 ÷ 300 mm.

Inserts such as doors, windows and door-window frames, can be made of polypropylene material and can be screwed onto the external side-elements or to the false-formwork by means of special permanent magnets.

The casting-side plate is normally 8 or 10 mm. thick.

It is possible to integrate this system with:

- concrete compacting by means of pneumatic vibrating system;

- concrete compacting by means of high frequency remote-controlled electrical vibrating system;

- accelerated concrete curing by steam, water, oil or electricity with electronic management of curing cycles;

- design-made special moulding with magnetic fixing system.

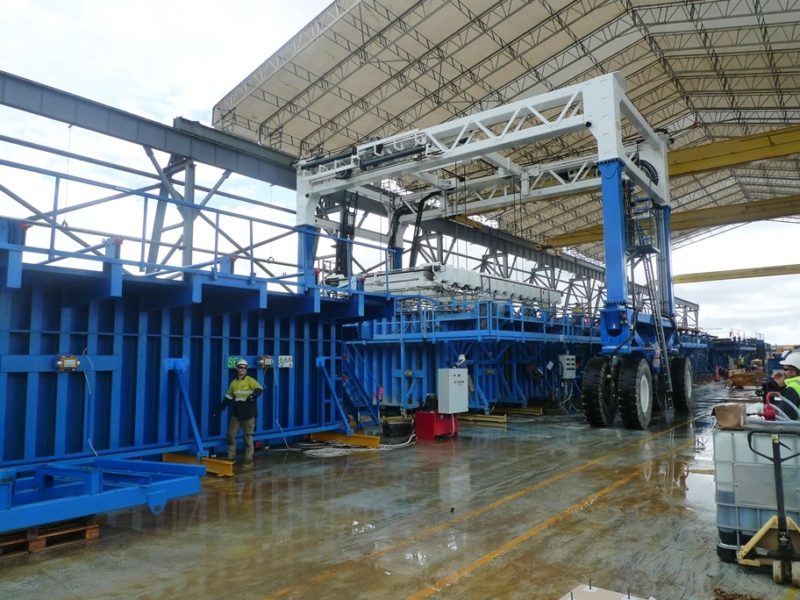

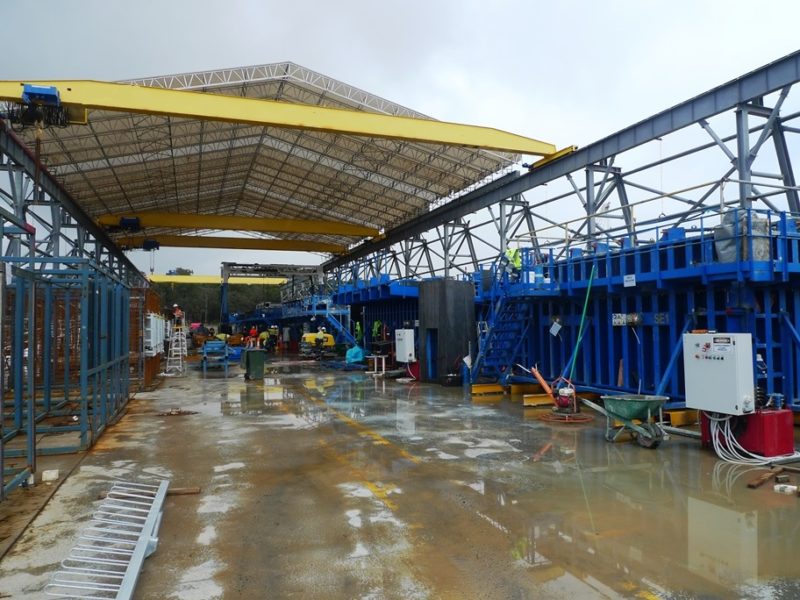

Formworks for cabins / power sub-stations

The installation for manufacturing cabins for power sub-stations mainly consists of:

- no.1 module-type formwork to manufacture the single-block cell element (4 walls + bottom slab);

- no.1 module-type formwork (table) to produce the roof element;

- no.1 turning machine of suitably sized capacity to rotate 0-90-0° the pre-cast cell and apply the roof element on top of it.

Any other internal elements (as false-floors and /or partition walls) can be separately cast on a table-formwork as well and be separately applied to the single-block element.

Precast elements

By these precasting technological solutions you can manufacture precast elements such as the following:

Necessari

Necessari

Funzionali

Funzionali

Statistiche

Statistiche Marketing

Marketing